Considerations in Warehouse Design for Industrial Occupiers

Designing a warehouse can be a daunting task. Producers, manufacturers, and shippers all have different objectives that must be met to create an optimal warehouse operation. To make it even more challenging, warehouse operators must determine the right building in the right location that can accommodate the intended use - a challenge in any tight real estate market. Regardless of market conditions, operations must drive warehouse design and real estate selection.

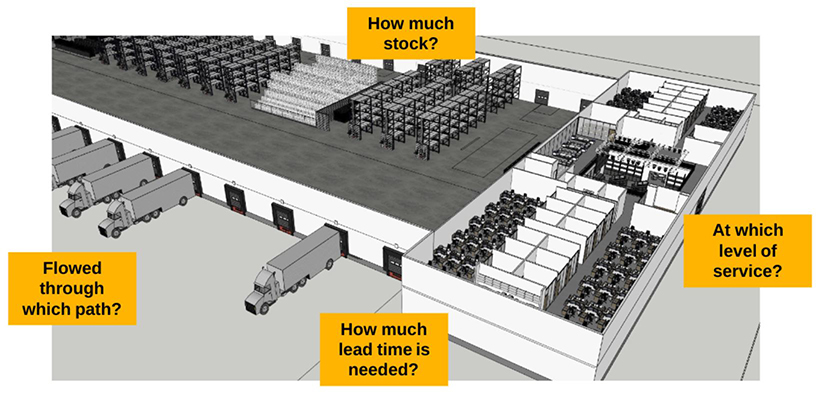

The objective of a warehouse can fall into multiple categories that will all influence the warehouse’s location proximate to a certain population, size, depth, clear height, power, fire suppression, loading, and technology. It’s very important to clearly understand the objectives prior to selecting a facility.

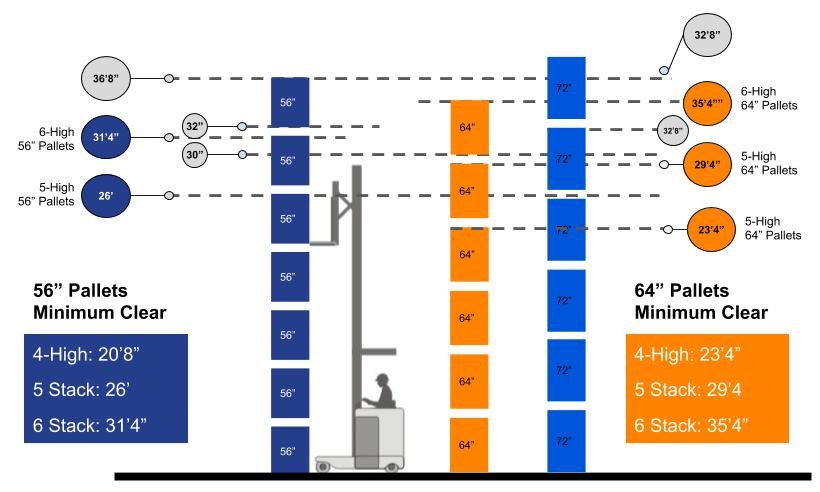

The second principal of warehouse design is to understand the volumes of goods stored, produced, and flowed through the building. An occupier must make important decisions on processes which will impact where and how materials are placed, racked, high-piled, or processed. This will also lead to critical decisions on warehouse loading equipment and proper investment in material handling. Differences in cube size and even inches in clear height can translate to a 20% swing in capacity.

Once volumes are determined a warehouse occupier will then select the mechanical systems to be placed in the warehouse. These systems consist of static racking, double stacked racks, conveyor belts, mezzanine levels, leveler equipment, and carousels. These systems must match the size, velocity, and volume of freight. A warehouse designer must ensure the implementation of storage modes is appropriate for the given operation.

The next principal of warehouse design is flow. It is critical to design a warehouse flow where free movement has a priority over storage capacity. By selecting a facility that accounts for the seasonal swing in volumes a warehouse occupier will avoid bottlenecks, unneeded motion, or long and frequent material handling runs. It is also important to be aware of building depth that would lead to inefficiencies in front or rear-load buildings. Alternatively, through planning in advance, companies can engage 3rd parties for additional needs or select an alternative facility if sustained growth is likely.

Material handling involves two critical cost components of warehouse operations: labor and capital investment. The capital expense of certain deep reach forklifts or those suitable for 32'+ clear buildings must be weighed against lease term and building cost (PSF v Cubic Ft). 2x deep or 34' clear racking will require larger more expensive forklifts and additional training. Simply put, the less goods are touched, the lower labor and material handling costs will be.

Reviewing each of these considerations with a holistic approach to warehouse design will ensure a successful operation. In many cases, this will also involve outside-the-box analysis that will look at network locations, inventory levels at distribution and final destinations, and associated transportation variables. For this reason a team of integrated experts should be engaged ‘in-concert’ to determine magnitudes of critical cost centers.